Transfer Dies

The presses that use this technology have a manipulator-transfer that enables the shift of the pieces from one station to the next one. The starting point is a steel blank which has been previously cut. That avoids the necessity of any attachment strip between pieces and consequently reduces the amount of raw material to be used.

This makes possible the fully automatic transition from one station to the next one.

In our press we additionally use a zig-zag feeder, which allows us to obtain an extra raw material saving in those pieces with circular blank shape.

This technology guarantees as well the highest benefits and productivity. Therefore it is suitable for big manufacturing series of those pieces which are not, due to their complexity or drawing shape, recommended to be produced by progressive stamping process.

Press Release

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

Read More 2020 A+ Project with Czech for high power Fuel Cell

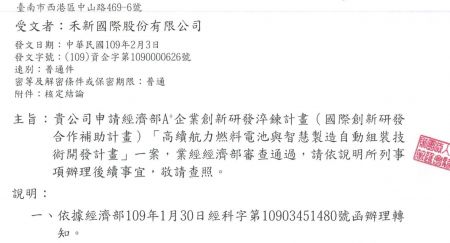

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More