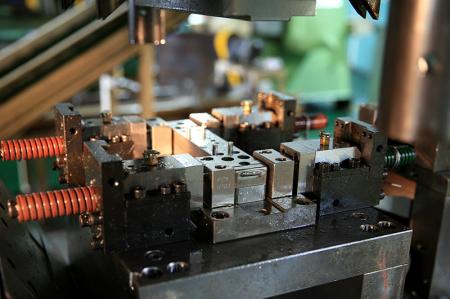

Stamping Shop

We offer state-of-the-art mechanical press control packages, modern transfer and progressive stamping presses, automatic coil feeders. We currently produce precise metal stampings for the following: Door locks, Electronics, Medical application, Automotive, Heat spreader, Metal Bipolar Plates for the Fuel Cell and Telecommunications industries.

We 16 sets of stamping presses ranging from 35 tons to 400 tons with table size up to 2.8meters long.

Progressive Stamping

Typical material we work with are all types of steel, hot and cold carbon steel, with or without galvanizing, stainless steel, aluminum and copper alloy. Regarding thickness, we go up to 9 mm.

Our orientation is the development and production of highly technical parts, with as much added value as possible, whether due to dimensional or quality requirements. Moreover, we are able to use specific equipment which allows to make additional operations inside the stamping tools, operations such as screw and nuts insert, threads and others.

Fine Blanking

Fine blanking is one of the special process offering our clients a wider range of components, as well as more complicated ones. Fine blanking has some common elements with regular stamping: press, die and coil. However, thanks to its specific working system, it allows to obtain much better results in terms of:

● Dimensional Tolerance in Cutting

● Flatness

● Cutting Without Tears

Regarding material types, we work mainly with cold steels, with specific characteristics to allow heat treatments. We also use different types of stainless steel.

Transfer Stamping

The presses that use this technology have a manipulator-transfer that enables the shift of the pieces from one station to the next one. The starting point is a steel blank which has been previously cut. That avoids the necessity of any attachment strip between pieces and consequently reduces the amount of raw material to be used.

This makes possible the fully automatic transition from one station to the next one.

Our specialty in this field is the production of moderate- or deep-drawing pieces, usually of cup shape: sealing elements, bearing housings, etc.

Press Machine List

| Name | Brand | Ton | Q'ty | Spec. |

|---|---|---|---|---|

| Press Machine | MAZUM | 20T | 3 | 320 x 625 x 200 |

| Press Machine | MAZUM | 25T | 1 | 320 x 625 x 230 |

| High Speed Press Machine | SENSON | 35T | 2 | 400 x 720 x 230 |

| Press Machine | SSC | 35T | 1 | 400 x 780 x 250 |

| Speed Press Machine | CHIN FONG | 45T | 1 | 460 x 725 x 230 |

| Press Machine | CHIN FONG | 60T | 1 | 550 x 1100 x 360 |

| Press Machine | CHIN FONG | 80T | 1 | 560 x 420 x 330 |

| Press Machine | MAZUM | 85T | 1 | 1000 x 550 x 360 |

| Press Machine | CHIN FONG | 110T | 1 | 600 x 1150 x 350 |

| Link Motion Press Machine | SANES | 120T | 1 | 750 x 850 x 375 |

| Press Machine with Transfer System | SEI YI | 160T | 1 | 2000 x 880 x 450 |

| Press Machine | CHIN FONG | 200T | 1 | 2200 x 940 x 510 |

| Press Machine with Transfer System | SENSON | 200T | 1 | 2200 x 940 x 510 |

| Knuckle Joint Press Machine with Transfer System | CHIN FONG | 400T | 1 | 2200 x 940 x 510 |

Press Release

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

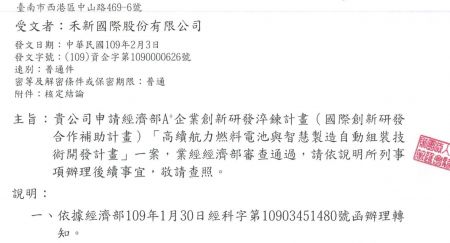

Read More 2020 A+ Project with Czech for high power Fuel Cell

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More