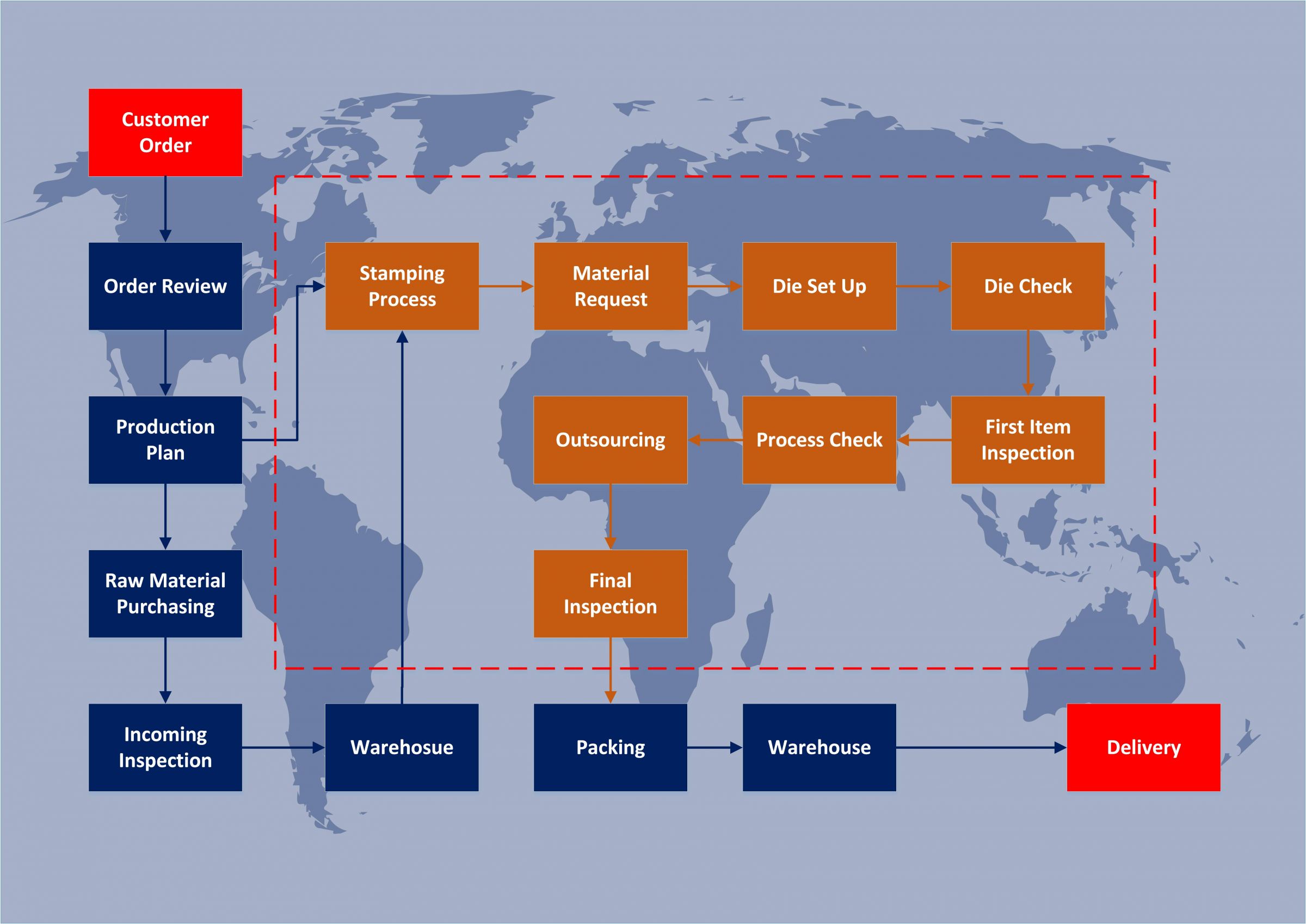

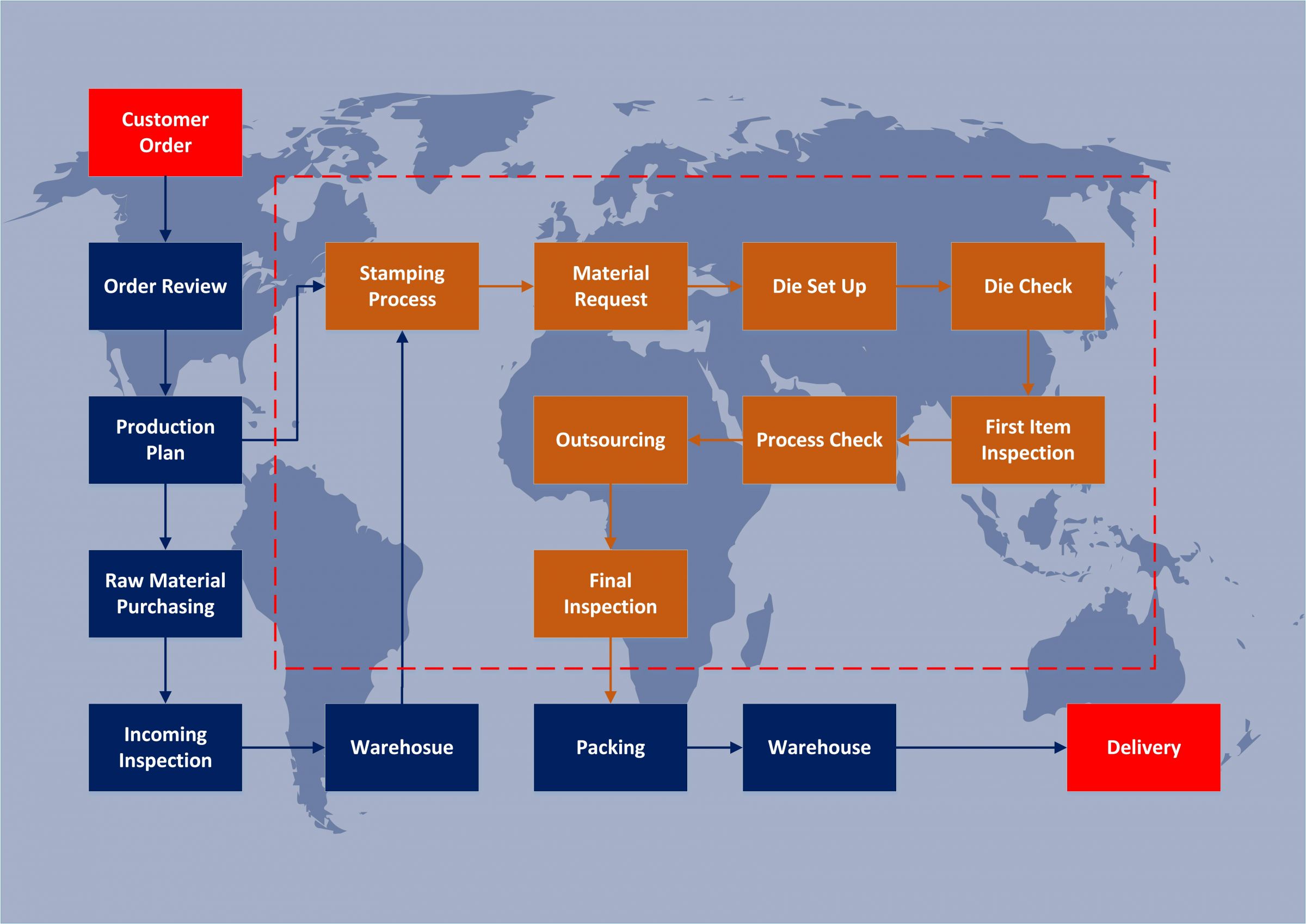

Stamping Production Flow Chart

Stamping Process,Material Request,Die Set Up,Die Check,First Item Inspection,Process Check,Outsourcing,Final Inspection,Packing

Features

We apply all the dies approved by customers to produce the stamping part and then the parts were inspected by our quality department complied with each commitment specification of customer accordingly.

Press Release

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

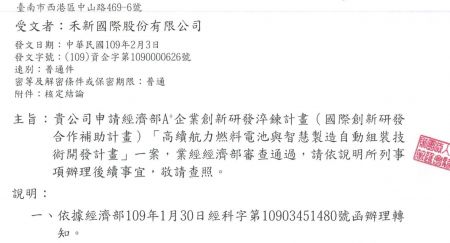

Read More 2020 A+ Project with Czech for high power Fuel Cell

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More