About LEADTECH

The president, Mr. Tong-Cheng Lee, of ENDWELL Enterprise Co., Ltd. has been working on the design and development of precision stamping dies for over 42 years. So far, we have successfully built more than 5,000 dies for our domestic and foreign customers.

To extend the services for our customers, we established LEADTECH International Co., Ltd. for metal stamping production. With company capital of US$2,000,000 and premises area of 31,200 square feet. We are a professional manufacturer of stamping dies and stamped parts in Taiwan. The industries that we serve are consumer electronics, telecommunications, automotive, door locks, fastener, aerospace, medical application and many other hardware industries.

We offer customer one stop service from DFM → Die Design → Die Build → Stamping Production → Surface Treatment → Assembly to finished products. All of our manufacturing processes are monitored by the MRP system for product traceability and meets customer delivery requirements.

We have operated the company with the management philosophy of "Outstanding", "Innovation" and "Commitment". Pursuing outstanding achievement, innovative concept design and carry out commitment to customers and employees.

Company Milestone

| Year | Achievement |

|---|---|

| 2017 | Purchased Japan KITAMURA CNC Milling Machine. Obtained subsidies from Bureau of Energy for the kW-scale metal plate fuel cell stacks with high power development plan. |

| 2016 | Obtained subsidies from Bureau of Energy for metal based fuel cell stacks technology with high power development plan. Acquired the Industrial Development Bureau, MOEA to subsidize the wedge locking washers development plan. ISO9002 certified by SGS. |

| 2015 | Obtained subsidies from Bureau of Energy for metal plate fuel cell stacks development. |

| 2013 | Purchased CHMER linear guideway Wire EDM. |

| 2012 | Purchased CHIN FONG 400 tons Knuckle Joint Press Machine with transfer system. |

| 2006 | TS16949 certified by SGS. |

| 2003 | Introduced ERP management system for stamping plant. |

| 1999 | ISO 9000 certified by SGS. |

| 1998 | Purchased American CINCINNATI CNC milling machine center and Swiss AGIE Wire EDM. |

| 1997 | Moved to Sigang factory area in Tainan City, with expansion of 3,500 square meters. |

| 1995 | Purchased Japan MITSUI SEIKI precision CNC Jigs grinder. |

| 1994 | Founded Leadtech International Co., Ltd. to provide customers with professional stamped products production services. |

| 1993 | Introduced stamping die design software: LIFECAD |

| 1991 | Introduced MIS stamping die management system, purchased first CNC milling machine center in the same year. |

| 1987 | Purchased the second CNC Wire EDM from Seibu of Japan. |

| 1984 | Purchased the first CNC Wire EDM from Seibu, Japan. |

| 1976 | Established Endwell Enterprise Co., Ltd. in Yongkang, Tainan City, covering an area of 320 square meters. |

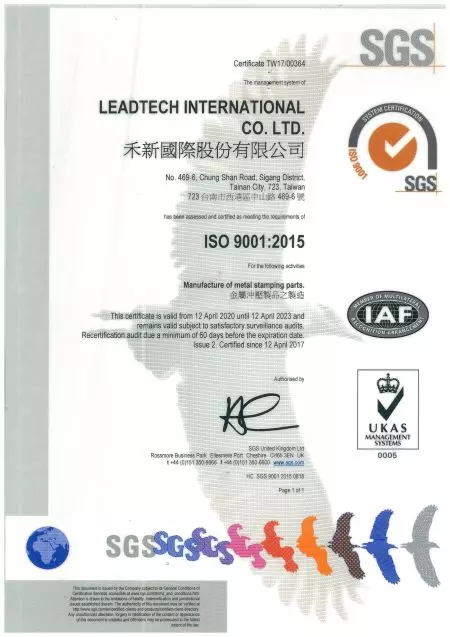

ISO Certificate

Leadtech International Co., Ltd. Got the SGS ISO 9001 certification in 1999. We strictly control the products' quality and gain our customers' long-term trust.

Major Customers

| Company Logo | Company Name | Major Industries |

|---|---|---|

| ASSA ABLOY GROUP - GLOBAL | Door Locks |

| GM MOTOR - USA | Automotive |

| OSRAM - USA | Light |

| SanRex - JAPAN | Semiconductors Power Supplies Welding Products |

| ALFANAR - SAUDI ARABIA | Low, medium and high voltage electrical construction products |

| HAVELLS - INDIA | Fast Moving Electrical Goods |

| TONG YANG GROUP - TAIWAN | Auto Parts |

| SUNUP - TAIWAN | Bicycle USB charger dynamo |

- Certificates

Press Release

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

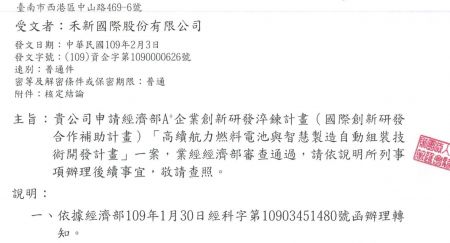

Read More 2020 A+ Project with Czech for high power Fuel Cell

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More