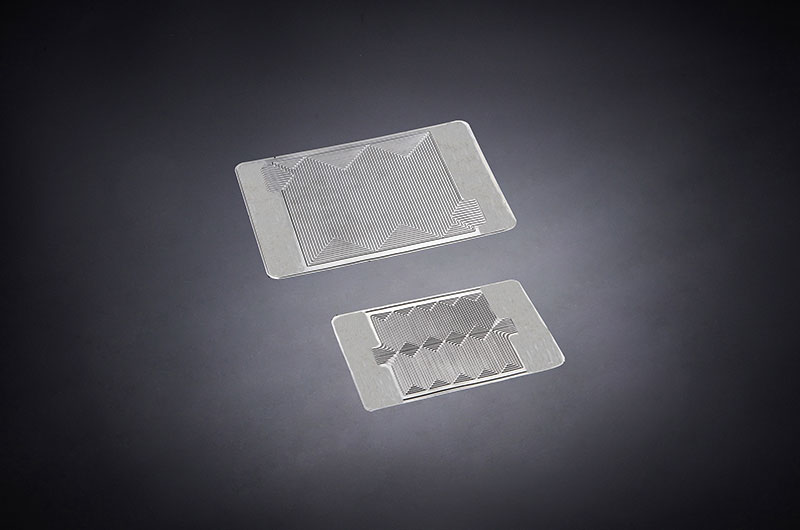

Bipolar Metal Plate for Fuel Cell

PEMFC,PEM,Alternative energy,Green energy,Hydrogen power,Hydrogen economics

The bipolar plates are the key components of the proton exchange membrane fuel cells. Properties required for the bipolar plates are high electric conductivity, high corrosion resistance, high mechanical strength, high gas impermeability, light materials, and low cost.

We use 400 Tons of press machine to punch the stamped parts and the Die size is up to 600 x 2500mm.

Specification

- Material: SUS304, SUS316L

- Thickness: 0.1 ~ 0.25mm

- Produced by: Transfer Die

- Movies

Press Release

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

Read More 2020 A+ Project with Czech for high power Fuel Cell

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More