How Can Taiwan-Made Progressive Dies Improve Your Stamping Operation's Efficiency?

LEADTECH's progressive dies are engineered to maximize your stamping operation's efficiency with cycle times up to 40% faster than conventional dies. Our precision-crafted tools maintain tight tolerances even at high production speeds, dramatically reducing scrap rates and quality issues. The modular design with common die sets allows for quick changeovers and simplified maintenance, minimizing costly downtime. With 48 years of metal stamping expertise, we deliver dies that not only improve part quality but also significantly enhance your production throughput and bottom line.

Our innovative approach to progressive die design incorporates common die sets that enable quick setup times and reduced downtime during production runs. By engineering only the core components specific to each application, we significantly lower our customers' investment in new tooling while maintaining the highest standards of precision and durability. This modular approach provides outstanding flexibility for various metal stamping requirements while delivering the exacting tolerances and surface finishes demanded by global industry leaders across automotive, medical, and consumer product sectors.

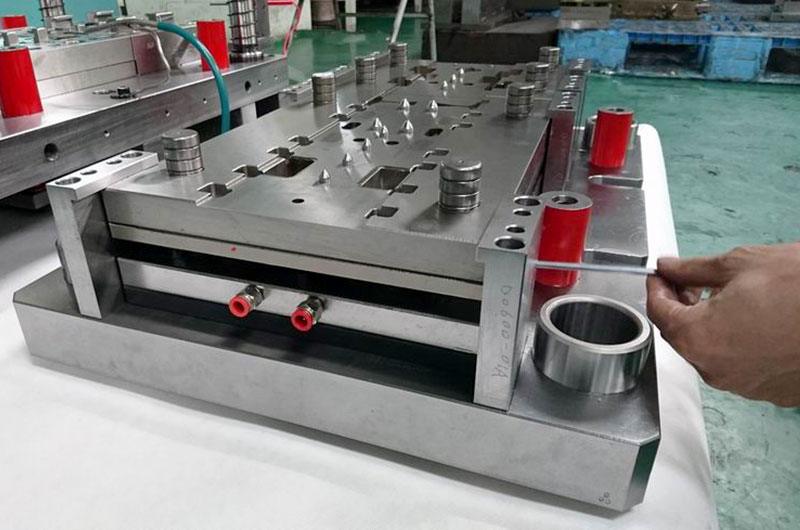

Progressive Dies

We offer high-quality, reliable and cost-effective progressive dies for the automotive, medical, office furniture, lock parts, metal bipolar plate for fuel cell....etc. Our internal progressive dies are designed with common die sets for quick set up. Only core components are built to reduce customer's investment in new tooling's.

Press Release

Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More 2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

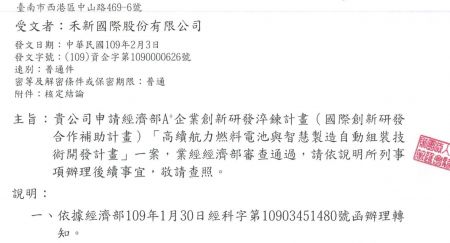

Read More 2020 A+ Project with Czech for high power Fuel Cell

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More 2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

Read More