-

Automotive Fuel Supply System Parts

We use 80 ~ 200 Tons of press machine to punch the stamped parts and the Die size is up to 500 x 1500mm.

-

Automotive Power Window Motor Housing

We use 160 ~400 Tons of press machine with robust transfer system to produce parts at maxium 60 strokes per minute and the Die size is up to 450 x 2000mm. Dies are designed with built-in cooling to ensure die temperture is controlled during mass production.

-

Motor-Cover

The stamped parts are punched by 300Tons of press machine and the Die size is up to 300 x 2200mm.

-

Automotive Power Window Motor Housing

We use 250Tons of press machine to punch the stamped parts and the Die size is up to 400*2000mm.

-

Automotive Fuel Supply System Part

The stamped parts are punched by 80 Tons of press machine and the Die size is up to 350 x 1200mm.

-

Automotive Power Window Motor Housing

We use 250Tons of press machine to punch the stamped parts and the Die size is up to 400 x 2500mm.

-

Automotive Transmission Parts

The stamped parts are punched by 120 ~ 400 Tons of press machine and the Die size is up to 450 x 2000mm.

-

Safety Belt Parts

We use 160 ~ 200 Tons of press machine to punch the stamped parts and the Die size is up to 450 x 2000mm.

-

Automotive Brake Parts

The stamped parts are punched by 110 ~ 300 Tons of press machine and the Die size is up to 500 x 2000mm.

-

Power Window Roller Curtain Blinds

We use 200 ~ 300 Tons of press machine to punch the stamped parts and the Die size is up to 1000 x 1800mm.

-

Automotive Body Bracket

The stamped parts are punched by 200 ~ 300 Tons of press machine and the Die size is up to 800 x 2200mm.

-

Automotive Fuel Supply System Parts

We use 80 ~ 120 Tons of press machine to punch the stamped parts and the Die size is up to 500 x 1200mm.

-

Transmission Parts

We use 120 ~ 200 Tons of press machine to punch the stamped parts and the Die size is up to 600 x 1800mm.

Press Release

-

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )

2017 Energy Project (Bureau of Energy, Ministry Economic Affairs )LeadTech has developed the first 10 kw of fuel cell with metal bipolar plates and generate the power successfully.

Read More -

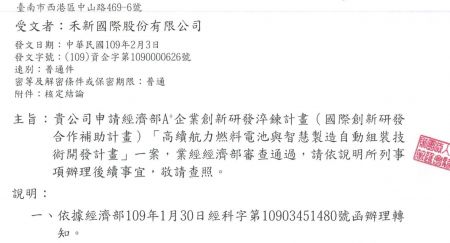

2020 A+ Project with Czech for high power Fuel Cell

2020 A+ Project with Czech for high power Fuel CellLeadTech got 40 million NTD subsidy from the Government to conduct an A+ Project with Czech for 30 months period.

Read More -

Invest 90 million to implement AI concept in LeadTech plant

Invest 90 million to implement AI concept in LeadTech plantLeadTech has been approved by Investment Taiwan Office (Ministry Economic Affairs, ROC) to invest 90 million NTD for new production line for the metal bipolar plate of Fuel Cell.

Read More